Dimensional Metrology

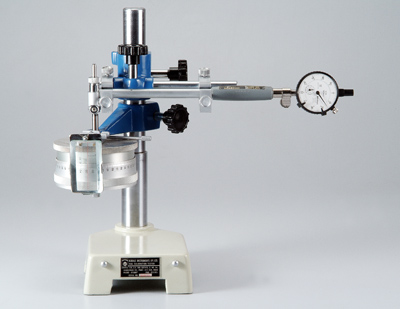

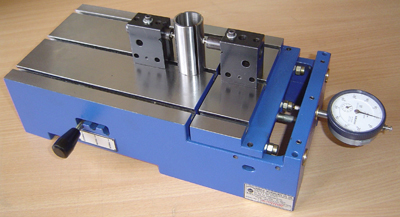

Dial Calibration Tester : Least Count 0.001 mm, Range : 25 mm:

Useful for periodic calibration of plunger type, lever Type dial gauges and bore gauges. Available in imperial and metric systems.PDF Download

.

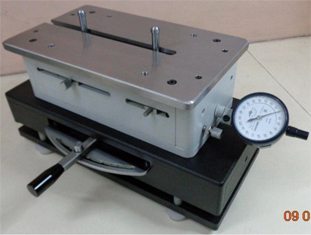

Dial Calibration Tester : Least Count 0.0002 mm, Range : 25 mm

Useful for periodic calibration of plunger type, lever Type dial gauges

and bore gauges.PDF Download

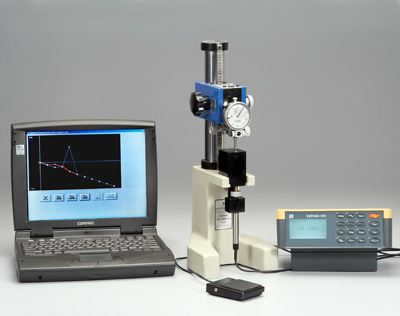

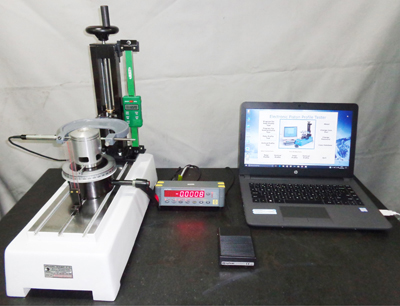

Elelectronic Dial Calibration Tester : Least Count 0.0001 mm, Range :10/25 mm:

Useful for periodic calibration of plunger type and lever type Dial gauges and bore gauges.The unit can be computer interfaced with user-friendly software for statistical analysis of measured values. PDF Download

.

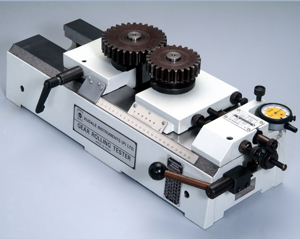

Gear ROLL Tester : DO-0

Useful for checking total composite error, tooth to tooth error of Helical

and Spur Gears.PDF Download

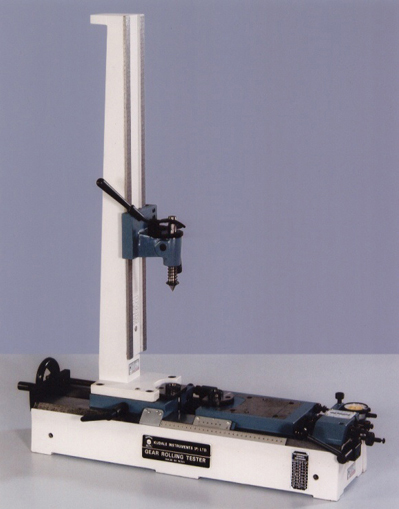

Gear ROLL Tester : ( P0)

(Model GRT P-0)

Useful for checking total composite error, tooth to tooth error of Helical and Spur Gears. Maximum Gear diameter 200 mm. The High Center Attachment (column) is available for inspection of shaft gear of length up-to 220 mm, as an optional accessory.

Gear ROLL Tester (Model GRT p-1)

Useful for checking total composite error, tooth to tooth error of Spur and Helical Gears. Available on demand the attachments for shaft gears, worm gears and Bevel gears and short center attachment for smaller gears. Center Distance 60 mm to 320 mm. Short center Attachment is available to inspect the gears with Center Distance 25 mm. Shaft Gears up to Length: 700 mm max. also can be inspected.

Indexing Fixture For Gear Roll Tester :

The indexing fixture is offered on Gear Tester, Model P-1 and P-2 only. The fixture is useful for inspection of shaft gear. With the fixture maximum 5 Nos. of Master Gears are mounted on different mandrels at a time and gears on shaft can be inspected one-after-another by meshing with the respective master gear.

.

Gear Roll Tester (Model GRT P-2) :

Useful for checking total composite error, tooth to tooth error. Available on demand the attachments for shaft gears, worm gears and Bevel gears and short center attachment for smaller gears. Center Distance GRT-P2 40 mm to 350 mm Shaft Gear Length: 700 mm max. PDF Download

Duplex Computerized Gear Roll Tester:

This is two stations Computerized Gear Rolling Tester for inspecting two Spur

or Helical identical gears. While one gear is inspected, the other will be loaded which

will save time for inspection. The graphical results are shown through computer software.

The machine is controlled through the AC Servo motor & AC Servo Drive. The

LVDT probe will record the variation in TCE, TTE, and Center Distance Variation. Then

data is transfer to Digital Read Out System as well as software. PDF Download

Computerized Gear Rolling Tester :

The fully automatic Computerized and Motorized Gear Roll Tester is useful for inspection of total composite error, tooth to tooth error and Run out of gears. The test report is generated in graphical format and indicating unit shows the accept / reject results based on pre-determined entered values. The high spot pen marking attachment is also offered as per demand. This instrument is offered with our models P-1 and P-2. PDF Download

Bevel Gear Tester : KIPL 140

The Bevel Gear Tester is useful for inspection of bevel gears in double flank method. The measurement of clearance of gear flanks and detection of bearing areas, inspection of composite error and checking of assembly distances are the applications of this instrument. Maximum bevel gear diameter 140 mm. Angle adjustment of axes 50° to 140°. Bevel Gears with min. assembly distance of 35 mm and Maximum assembly distance of 140 mm can be inspected,also bigger model 200 mm available on demand.

PDF Download

Motorized Bevel Gear Tester: KIPL 300

The Bevel Gear Tester is an unique solution for testing the Bevel Gear assemblies during production and final inspection. The tester allows adjustment of production machines for bevel gearing and bevel gears assembly. It is necessary to check the above parameters for the users and manufacturers of bevel gears. The tester helps shorten the setting-up time and secures the assembly dimensions. The instrument is motorized for rotating the bevel gear under inspection. Due to motorization the inspection time is reduced accuracy of inspection is enhanced and thus the motorized BGT has eased bevel gear inspection. The instrument consists of precisely machined rigid Cast iron semi- circular base with two swiveling arm assemblies. The arm assemblies revolve around the bush mounted on the base. The rotors are mounted in cylinders of arm assemblies. The rotors actuate on spring pressure. The setting mandrel is mounted in bore of bush on the base, to set assembly distance. A pair of bevel gear to be checked on the machine is required to mount on mandrels on the rotor's bore. Before that the calculated slip gauge size is used for setting specified assembly distance between gear mandrels and bush mandrels. With the help of Dial gauge, the assembly distance can be set. Angular separation of both the arm assemblies can be set by slip gauge size between bottom disk of arm assembly and triangular plate on base.

After setting of assembly distance and angle between arm assemblies, the gears are mounted on respective mandrels. The dial gauges on arm assemblies are used for measuring actual centre distance and total composite error by double flank rolling separately.

PDF Download

Scale And Tape Calibration Unit: 1000 mm

The scale and Tape calibration unit is useful for calibration of measuring tapes and scales. The Range of unit is 1000 mm. with the Least Count of 0.005 mm. The instrument is fitted with high precision scale and Digital Indicator. The CCD Camera catches the image of measurement line on scale or tape, under calibration and the same is displayed on small video screen. PDF Download .

Precision Bore Comparator :

Useful for checking Internal Diameter, Groove Diameter of Bore, Plain Internal Diameter, Internal Tapered diameter, Internal Pitch diameter and internal raceway diameter of machined parts. Measuring Range (Diameter): 4 - 67 mm. Measuring Range (Height): 0 - 12 mm. PDF Download

Check Master :

(The Inspection Gauging Unit):

This instrument finds its application on shop floor as well as in the Gauge Room for inspection of Internal Diameter, Outside Diameter, Run-out, Composite error of gears, Thickness etc. parameters of machined parts. The instrument is popularly used on shop floor as a comparator for stage inspection and final inspection. We offer special tooling on the instrument as per customer requirement to meet inspection requirement of the components.

PDF Download .

.

Electronic Piston Profile Tester:

The instrument is used for various vital acceptance parameters of Piston. The parameters such as Ovality, Taper over the length and angular difference between major and minor diameter of Piston can be checked. The instrument is provided with high accuracy electronic probe, digital indicating unit and specially designed software to check the above parameters of pistons. The test data can be stored on PC.PDF Download .

Scale & Tape Calibration Unit :2000 mm

The measuring tapes and scales play very important role in the field of engineering. The applications of these measuring tools are very wide from civil, mechanical to textile industry and also in society at large. Hence, it is necessary to calibrate tapes and scales with great precision, to maintain high measurement standards of the same. The scale and tape calibration unit is unique solution for calibrating different measuring scales/tapes.

The scale and Tape calibration unit is useful for calibration of measuring tapes and scales. The Range of unit is 2000 mm. with the Least Count of 0.005 / 0.001 mm. The instrument is fitted with high precision scale and Digital Indicator. The Microscope catches the image of measurement line on scale or tape, under calibration and the same is displayed on PC. .PDF Download .

Scale and Tape calibration unit: 1000 mm

The scale and Tape calibration unit is useful for calibration of measuring tapes and scales. The Range of unit is 1000 mm. with the Least Count Of 0.005 / 0.001 mm. The instrument is fitted with high precision scale and Digital Indicator. The Microscope catches the image of measurement line on scale or tape, under calibration and the same is displayed on PC.

.

Universal Bench Comparator (UBC)

The Universal Bench Comparator is a workshop

quality system for undertaking internal and

external inspection on a range of work pieces.

The unit is user friendly to set quickly and

accurately for particular application. The

standard unit is available with various optional

measuring anvils to cover a large variety of

inspection tasks.

Features:

Robust Aluminum construction.

Adjustable Measuring Pressure.

Highly Sensitive Linear motion Mechanism.

Adjustable and moving Anvil station.

Dial / Probe mounting holder of hole dia 8 mm.

Different measuring levels (heights) upto 25 mm for dia

check.

Inside and outside- Fast and precise measurements.

Hardened measuring top table surface made of stainless steel.

Special Tooling design facility against demand.